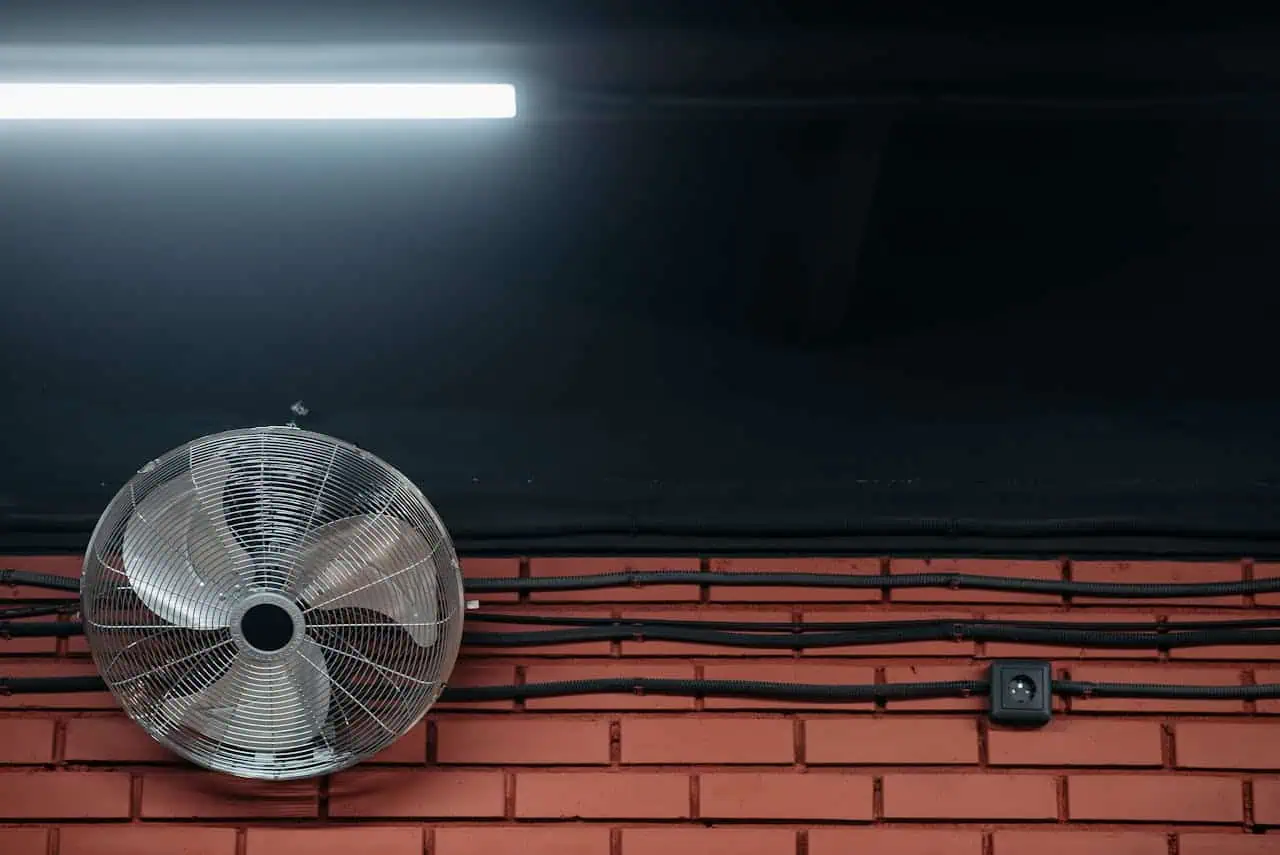

Industrial fans play a crucial role in many commercial and manufacturing settings, providing airflow, temperature regulation, and ventilation to create safer and more productive environments. Among these, the Fan TL140 115 60 10Y TL .75 1500 is known for its reliability and efficiency, making it a popular choice for HVAC (heating, ventilation, and air conditioning) systems in the United States. This guide will break down its specifications, practical applications, installation methods, maintenance tips, and more.

1. Understanding Fan Model Numbers and Their Importance

If you’re familiar with industrial equipment, you’ve probably encountered products named with complex codes. These numbers aren’t just random—they give vital information about the fan’s design, power, and usage. Here’s a breakdown of Fan TL140 115 60 10Y TL .75 1500:

- TL140: Likely refers to the model or series. This part identifies the fan’s design, size, and possibly its blade diameter or housing specifications.

- 115: This number represents voltage, in this case, 115V, standard for many U.S. commercial settings.

- 60: Refers to frequency in hertz (Hz), a key electrical specification in the U.S.

- 10Y: Might denote the fan’s configuration, mounting type, or specific features unique to the model.

- .75: Indicates horsepower (HP), giving a sense of the fan’s power.

- 1500: RPM (revolutions per minute), showing how fast the fan blades rotate, impacting airflow.

Understanding these numbers helps in matching the fan with the right settings and systems, ensuring compatibility and efficiency.

2. Technical Specifications of Fan TL140 115 60 10Y TL .75 1500

Voltage and Power

- With 115 volts, this fan is compatible with U.S. power standards, allowing it to be used in most commercial and industrial settings without needing a voltage converter.

Horsepower (.75 HP)

- .75 HP is significant for airflow but is still energy-efficient. This power level ensures that the fan can circulate a large volume of air without a massive energy draw, making it a balanced choice for continuous operation.

RPM (1500)

- 1500 RPM is relatively high for industrial fans, meaning this model can move air efficiently, keeping spaces well-ventilated. Higher RPM generally contributes to a greater CFM (cubic feet per minute), which is critical for cooling or ventilation.

Frequency (60 Hz)

- 60 Hz frequency is standard in the U.S., ensuring compatibility with U.S.-based power systems. Fans with matching frequency and voltage reduce the risk of operational issues and prolong the equipment’s lifespan.

Additional Specifications

- Depending on the model, the fan might also have specifications like blade diameter and housing material (often metal or durable plastic), as well as certifications (UL or CE ratings) for safety and performance standards.

3. Applications of Fan TL140 115 60 10Y TL .75 1500

Industrial and Commercial Use Cases

The TL140 model is versatile, finding applications across:

- Manufacturing Plants: For ventilation and air circulation to cool machinery.

- Warehouses: Maintaining airflow in large, enclosed spaces, crucial for worker comfort and safety.

- Data Centers: Controlling temperature around sensitive equipment.

- HVAC Systems: Used as part of comprehensive HVAC setups for reliable ventilation.

Environmental Considerations

- This fan performs well in environments where high airflow is needed to mitigate heat, humidity, or airborne particles. However, it may need additional protection in highly corrosive or high-humidity environments to extend its lifespan.

4. How to Install and Set Up Fan TL140 115 60 10Y TL .75 1500

Installation Requirements

- Tools Needed: Wrench, screwdriver, electrical connectors, mounting brackets.

- Mounting Options: Ceiling-mounted or wall-mounted, depending on space and application.

- Connection Points: Check voltage compatibility before connecting to the power source.

Step-by-Step Installation Guide

- Turn Off Power: Always disconnect power to prevent electrical hazards.

- Position and Mounting: Secure the fan to a stable surface using mounting brackets.

- Electrical Connection: Attach the fan’s wiring to the correct terminals, matching colors to avoid incorrect wiring.

- Secure and Test: Check that the fan is securely mounted, then power on to test functionality.

Safety Precautions

- Wear protective gloves and ensure that all wiring is insulated to avoid electric shock.

- Only install this fan in locations where it’s designed to operate (e.g., indoors or protected outdoor spaces).

5. Maintenance and Troubleshooting Tips

Regular Maintenance Schedule

- Monthly: Clean the blades to remove dust buildup, which can slow RPM and reduce airflow.

- Every Six Months: Check for any signs of wear, particularly around the motor and electrical connections. Inspect mounting brackets and bolts for stability.

- Annually: Apply lubricant to moving parts if needed, as recommended by the manufacturer.

Common Issues and Solutions

- Overheating: If the fan overheats, check for obstructions around the blades and ensure airflow is not restricted.

- Noisy Operation: Tighten any loose bolts or parts. Unusual noise may also indicate a motor problem.

- Reduced Airflow: Inspect for dust accumulation on blades and clean as needed.

When to Replace Parts

- Replace blades if they show signs of damage or imbalance.

- Motor or electrical parts may need replacement after several years, depending on the fan’s usage.

6. Energy Efficiency and Environmental Impact

Energy Consumption

- Operating at .75 HP and 1500 RPM, this fan balances power with efficiency, making it suitable for continuous use without excessive energy costs.

Energy-Saving Tips

- Smart HVAC Integration: Consider pairing with smart systems that optimize usage based on room occupancy.

- Optimal Positioning: Properly position the fan to maximize airflow, reducing the need for multiple fans.

Environmental Benefits

- Durable materials contribute to longevity, reducing waste. If available, models with recyclable components or low-energy certifications are ideal for eco-conscious facilities.

7. Buying Guide for Fan TL140 115 60 10Y TL .75 1500

Where to Buy

- Authorized Distributors: Check reputable industrial suppliers or online marketplaces like Grainger, Global Industrial, and Amazon Business.

- Local HVAC Supply Stores: Many HVAC suppliers carry industrial fans and offer in-person support.

Considerations When Buying

- Warranty: Look for options with a warranty, especially for industrial use.

- Brand Reputation: Buying from established brands ensures access to customer service and replacement parts.

Pricing Expectations

- This model generally falls within a range of $150 to $300, depending on the supplier and any included features or add-ons.

8. Comparison with Similar Fan Models

Similar Models from Competitors

- Fans from brands like Fantech, Dayton, and Broan-NuTone may offer comparable options with slight variations in horsepower, RPM, or special features like noise reduction.

Pros and Cons

- Pros: Reliable performance, compatible with U.S. power systems, affordable energy efficiency.

- Cons: Might lack specialized features like smart integration or variable speed control in some models.

9. Conclusion

The Fan TL140 115 60 10Y TL .75 1500 is a versatile and practical choice for industrial and commercial spaces, offering reliable airflow and efficient power usage. With proper installation, regular maintenance, and a solid understanding of its specifications, this fan can meet the demands of various environments. For anyone in the market for a robust, durable fan that’s compatible with standard U.S. power systems, this model provides a balanced solution that’s easy to install and maintain.